Preface

随着电力电子技术、控制技术和电力器件制作工艺的进步,变频器技术得到了迅速发展。变频器在风机、水泵、提升机、皮带机等领域的应用已相当成熟。传统的矿用皮带输送机通常采用工频拖动和液力耦合器传动,存在传动效率低、启动电流冲击及机械冲击大、无法实现功率平衡等问题,导致系统运行不经济;同时,皮带和液力耦合器的磨损严重,维修及维护成本高昂,还存在无功环流损耗。因此,对皮带运输机采用变频控制,能够有效降低企业生产成本,提高经济效益;控制系统本身良好的控制性能和完善的保护环节,能有效避免事故发生并延长皮带机的使用寿命。

With continuous advances in power electronics, control technology, and power device manufacturing, VFD (Variable Frequency Drive) technology has rapidly developed, becoming mature in applications such as fans, pumps, hoists and conveyor belts. Traditional mining conveyors typically use power-frequency drive and hydraulic couplers, resulting in low efficiency, high starting current and mechanical impact, and the inability to achieve power balance—making the system uneconomical. At the same time, belts and couplers suffer heavy wear, leading to high maintenance costs and reactive power circulation losses. Therefore, applying VFD control to belt conveyors effectively reduces production costs, improves operational efficiency, and enhances system reliability and protection, significantly extending the conveyor’s service life.

Customer Introduction

几内亚铁矿的皮带机运输是全矿的流程中枢,一旦皮带机无法正常工作,将导致全矿停产,造成巨大经济损失。因此,高压调速系统必须具备极高的可靠性、稳定性和防护性。

基于上述工作特点,变频器设计需满足以下主要技术条件:

The conveyor system is the central link of the entire Guinea iron mine. Any failure in the belt conveyor would lead to full-site shutdown and cause major economic losses. Therefore, the high-voltage speed-regulation system must provide exceptional reliability, stability and protection. Based on these operational characteristics, the VFD must meet the following requirements:

High reliability, stability and protective performance.

Bypass function for power-frequency operation during faults.

Smooth start with high starting torque.

Output torque ≥2× rated motor torque for large load variations and heavy-load restart.

Full compatibility with the mine’s control and monitoring interfaces.

Belt-inspection functionality.

经过对各类高压变频器厂家的调研和比较,几内亚项目最终选择了新风光JD-BP38系列高压变频器作为皮带机的控制设备,现场共配置多台集装箱式高压变频器进行控制。

After evaluating various suppliers, the project selected FGI’s JD-BP38 Series High-Voltage VFDs as the control solution, with multiple containerized HV VFD units deployed on site.

VFD Control Scheme for the Conveyor

Motor Drive Control Method

由于带式输送机的三台电机控制方式相互关联,为保证系统速度同步和电机转矩平衡,采用新风光自主研发的主从控制功能。一台变频器作为主机控制模式,其余两台为从机控制模式,跟随主电机速度同步运行,并以主电机转矩输出为依据,确保三台电机之间实现转矩平衡。

As the three motors operate in a linked manner, FGI’s self-developed master-slave control is adopted to ensure speed synchronization and torque balance. One VFD serves as the master, while the other two operate as slaves, following the master’s speed and torque commands to maintain real-time torque balance.

Basic Performance of the JD-BP38 High-Voltage VFD Series

根据现场需求,高压变频器需实现皮带系统的软启动和调速运行,采用矢量控制技术,满足皮带机重载启动、主从电机转矩均衡控制等功能,并具备高可靠性。

According to the site requirements, the high-voltage VFD shall provide soft start and speed regulation for the belt conveyor system. Vector control technology shall be adopted to meet the functions of heavy-load startup and torque balance control between master and slave motors, while ensuring high reliability.

Characteristics of FGI High-voltage Frequency Convertes

Multilevel cascaded topology with low harmonics; 33-level output requires no output filter and supports standard induction motors.

Sensor-less vector control with high starting torque, preventing over-current during load fluctuations.

Torque coordination for real-time balance in multi-motor systems.

Overload capability above 2× rated current for large-inertia heavy-load starts.

Wide grid-voltage adaptability (−65% to +115% Un) with advanced protections such as cell bypass, neutral-point shift, grid-frequency bypass and blackout restart, greatly enhancing reliability.

Main Circuit Wiring of the Conveyor VFD System

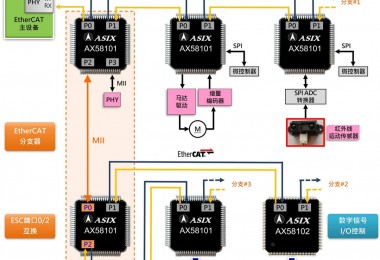

现场采用3套新JD-BP38系列高压变频调速系统,根据用户要求,变频器控制系统采用主从控制,“一拖一”控制方式。3台高压变频器主回路接线方式相同,以其中一台装置为例,一次接线如图

Three JD-BP38 HV VFD systems are deployed on site, using master-slave mode and “one-to-one” motor control. All three units share the same wiring configuration, shown in Figure 1.

一拖一接线柜(带缓冲)一次回路图

One-to-One Wiring Cabinet (with Buffer)

Primary Circuit Diagram

Master-Slave Control

如皮带系统简图所示,选用1#变频器为主变频器,2#和3#变频器为从变频器。操作台向主变频器发送给定频率值,主从变频器之间采用光纤通信,1#变频器作为主控,检测所有变频器的运行电流,计算并发出输出转矩给定值,控制从变频调速系统同步运行。

As shown in the simplified conveyor system diagram, VFD No.1 is selected as the master drive, while VFD No.2 and No.3 operate as slave drives. The control console sends the frequency command to the master VFD, and optical fiber communication is used between the master and slave VFDs. Acting as the master controller, VFD No.1 monitors the operating current of all VFDs, calculates the required torque output reference, and issues torque commands to ensure synchronized operation of the slave VFD systems.

高压变频调速系统简图(BC4A)

Simplified Diagram of the High-Voltage VFD Speed

Regulation System (BC4A)

Operating Process of the

VFD Electrical Control System

皮带电控系统控制原理图

The control principle of the conveyor electrical control system

Control Principle of

the Conveyor Electrical Control System

起车时,皮带电控系统首先对皮带系统传送的信号进行判断,如跑偏、堆铁、纵撕、急停闭锁等,若各信号正常,方可进入下一程序。

When starting, the conveyor electrical control system first checks all signals from the belt system—such as belt deviation, material buildup, longitudinal tear, and emergency stop interlock. Only if all signals are normal will the system proceed to the next step.

当皮带机各部分均处于正常状态,具备起车条件,才会发出启动信号。发出起车指令后,变频器启动。

When all parts of the belt conveyor are confirmed to be in normal condition and meet the start-up requirements, a start signal is issued. After the start command is sent, the VFD begins operation.

同时,操作台发出指令使抱闸打开,并检测抱闸是否完全打开。若抱闸未打开或未完全打开,将关闭运行信号,并给变频器发送抱闸信号使其急停,防止因堵转而过流跳闸。

At the same time, the control console sends a command to release the brake and monitors whether it is fully opened. If the brake does not open or fails to fully open, the system will disable the run command and send a brake signal to the VFD to perform an emergency stop, preventing overcurrent trips caused by motor stalling.

当皮带达到额定速度,电控系统实时检测皮带速度与滚筒速度,若二者速度差值超过规定值,紧急停车,并发出打滑报警信号。

When the belt reaches its rated speed, the control system continuously monitors the belt speed and drum speed. If the speed difference exceeds the specified limit, the system will execute an emergency stop and trigger a belt-slip alarm.

系统实时监测电机温度、减速器温度、轴承温度、皮带张力、电机电流、抱闸状态、变频状态等参数。一旦任一指标或状态出现异常,系统将立即紧急停车并发出报警信号。

The system continuously monitors parameters such as motor temperature, gearbox temperature, bearing temperature, belt tension, motor current, brake status, and VFD status. If any parameter or condition becomes abnormal, the system will immediately initiate an emergency shutdown and issue an alarm.

Effects of Using High-Voltage VFDs

to Drive the Conveyor

真正实现了皮带机的软启动。通过电机慢速启动,带动皮带机缓慢启动,逐步释放胶带内部贮存的能量,将输送机启停时产生的冲击降至最低,几乎不对胶带造成损害。

The conveyor achieves true soft starting. The motor starts slowly, driving the conveyor to accelerate gradually and releasing the internal stored energy of the belt step by step. This minimizes shock during start and stop processes and virtually eliminates belt damage.

有效降低胶带损耗。变频器的启动时间可在1至3600秒内灵活调整,皮带机的启动时间通常根据现场情况设定在60至120秒之间。

Belt wear is significantly reduced. The VFD’s start-up time can be flexibly adjusted between 1 and 3600 seconds, and the conveyor’s start-up time is typically set between 60 and 120 seconds depending on site conditions.

实现了皮带机三台电机驱动时的转矩平衡。电机驱动时采用主从控制方式,确保转矩平衡。

Torque balance among the three conveyor motors is achieved. The master-slave control method ensures balanced torque output during multi-motor operation.

具备验带功能。变频调速系统为无级调速的交流传动系统,在空载验带状态下,可调整0至100%额定带速范围内的任意带速。

The system supports belt-inspection mode. As a stepless AC drive system, it allows adjustment to any belt speed within 0–100% of the rated speed under no-load inspection conditions.

实现平稳的重载启动。变频器在低频运转时可输出2.2倍额定力矩,适用于重载启动。

Smooth heavy-load starting is achieved. The VFD can deliver up to 2.2 times the rated torque at low frequency, making it suitable for heavy-load start conditions.

Conclusion

皮带机的驱动系统采用新风光最新研制的高压变频器后,确保了运输皮带的稳定运行,配合自动控制系统,有效解决了皮带运输过程中的跑偏、堆煤、超温等问题,显著提升了皮带机的自动化控制水平。现场应用表明,利用技术先进、成熟可靠的高压变频调速系统拖动皮带机,不仅大幅提高了皮带机的自动化控制水平,还降低了现场维护量,带来显著的经济效益,值得大力推广。

With the adoption of FGI’s JD-BP38 series high-voltage VFDs, the conveyor drive system now operates with enhanced stability. Combined with the automated control system, it effectively resolves issues such as belt deviation, coal buildup, and overheating during operation, significantly improving the overall automation level. Field applications have demonstrated that using an advanced, mature, and reliable high-voltage VFD drive system for the conveyor not only greatly enhances automation but also reduces on-site maintenance workload and brings substantial economic benefits, making it highly worthy of widespread promotion.